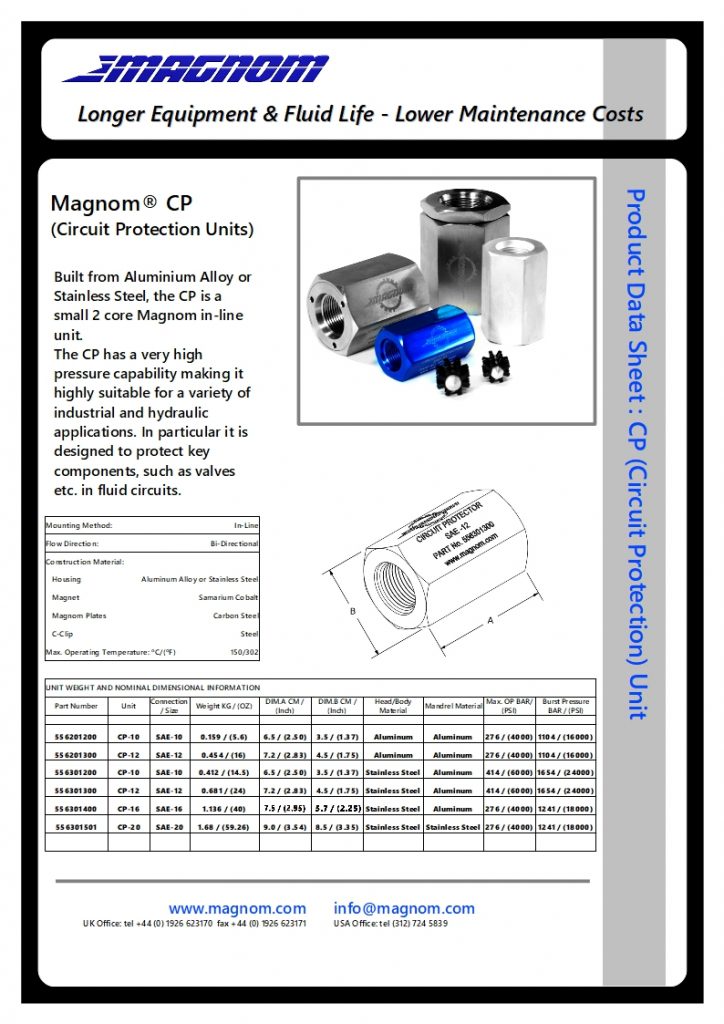

CP ‘Circuit Protection’ Products Range

For the very first time! Super Efficient – High Pressure – Non-Restrictive – Bi-Directional filters, to protect your critical valves, and main loop Hydrostatic systems, in a compact, versatile unit with a very high-pressure capability, making it ideal for critical component protection

Special Features and Benefits:-

- Non-Restrictive, virtually eliminating pressure drop

- Up-to 6000 psi (414 BAR) working

- Compact, High Capacity, Efficient system and component protection

- Standard SAE-12, -16 & -20 connections

- Bi-Directional

- 100% Efficient single pass to 4 micron

- Aluminium Alloy or Stainless Steel construction

- SAE-20 is Cleanable/Reusable

Applications

- Hydraulic Valve circuits

- Cylinder/actuator protection

- Hydrostatic systems

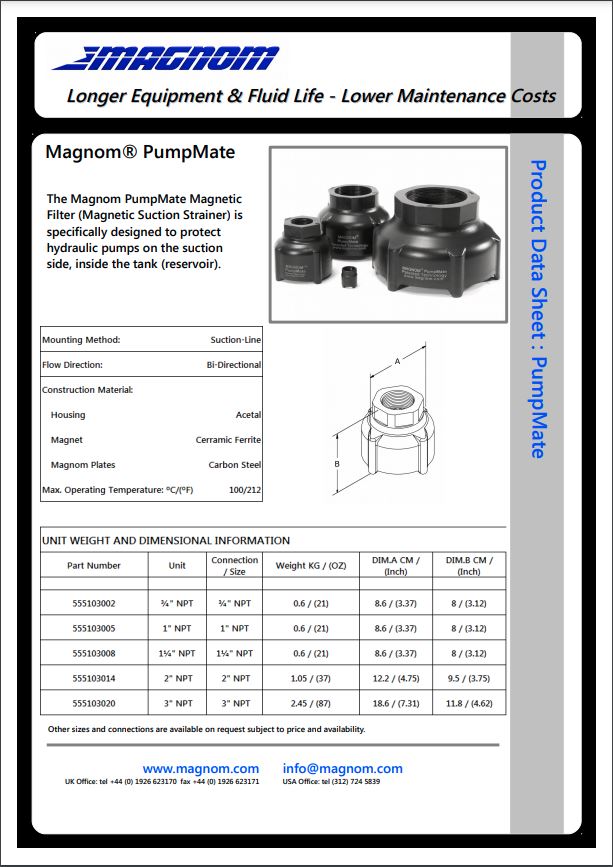

PUMP MATE “Pre-Pump Suction Protection”

For the very first time, The potential for “Fit & Forget” Pre-Pump protection,

Magnom™ PumpMate Magnetic Suction Strainer/filter is specifically designed to ‘protect’ hydraulic pumps on the suction side, as well as the entire fluid system, from inside the tank (reservoir).

The patented design cleans fluids re-pump ‘Without Restriction’

Magnom™ provides the performance of a 1 micron absolute hydraulic filter cartridge on the suction side of a pump.

This is accomplished without wash-off of collected particles, as seen with other magnetic devices,

This is ‘A generational leap in technology’ for the protection of critical hydraulic and lubrication pumps with virtually no pressure drop or restriction to flow, even when the PumpMate unit is ‘full’ of contaminant.

Special Features and Benefits:-

- Virtually no pressure drop (even when full)

With no pump cavitation, - Removes contamination to sub-micron levels

- Has an exceptionally high contaminant holding capacity (2” PM holds up-to, ½ Kg – 1lb of contamination)

- Offering OEMs and Operators a true ‘fit and forget’ solution

Applications

- Hydraulic & Lubrication, Mobile and static systems

- Pump & General total system protection

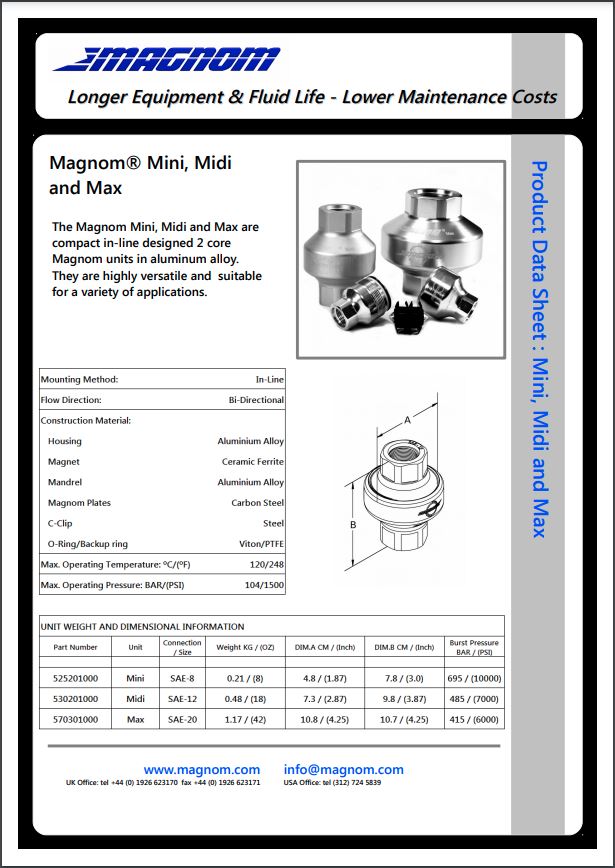

Mini, Midi, Max – General System Protection

The Mini Midi & Max products are the ‘work horse’ of the Magnom Product Range,

An in-line design constructed in rugged aluminium alloy these units have an excellent performance and a high contaminant holding capacity.

Special Features and Benefits:-

- SAE-8 -12 & -20 connections,

Bi-Directional, - No Pressure Drop (even when full)

- Up-to 100% efficient single pass

- Cleanable/reusable

Applications

- General Lubrication & Hydraulic Systems

- These Units are the Magnom™ of choice for fitment to lubricant and hydraulic systems and also to many larger industrial and off-highway Gearboxes & Transmissions

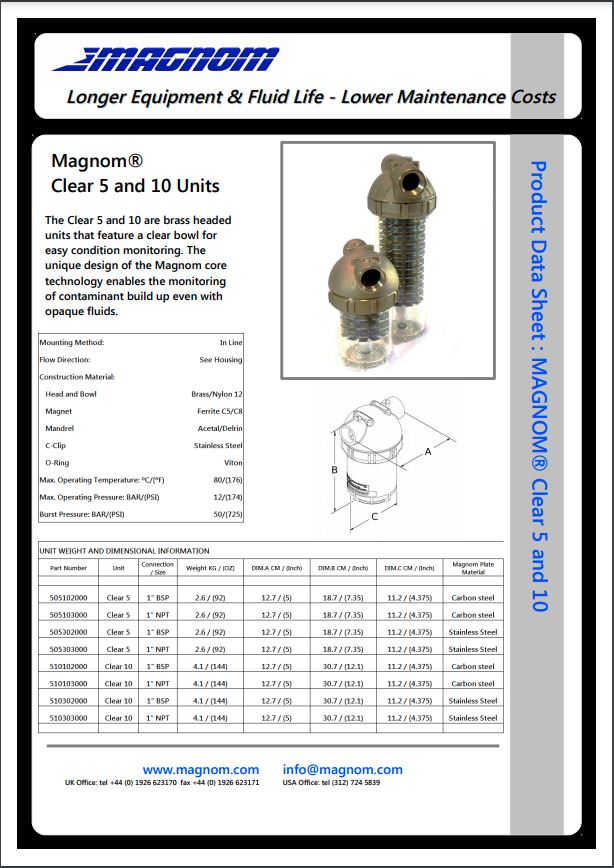

Clear 5 & 10 – Process & Machine Protection

The Clear 5 & 10 products have a brass-headed unit that couples to a Nylon 12 clear bowl for easy & obvious condition monitoring. The unique design of the Magnom™ core technology enables the monitoring of contaminant build-up even with opaque fluids.

The Nylon 12 bowl material allows the Clear 5 to be used in a wide range of temperatures

The Clear 5 can also be specified with stainless steel flux plates making it ideal for aqueous applications.

The Clear 10 is the same general specification as the Clear 5, and has double the contaminant capacity, up to 450g.

Special Features and Benefits:-

- Easy condition monitoring

- Available with stainless steel flux plates

- Ideal for water environments

- The temperature and pressure capability make the Clear 5 & 10 versatile units, often used in applications such as machine tool coolant and wash systems

- Cleanable/reusable

Applications

- Coolants

- Cutting Oils

- Water [Heating & Cooling]

- Wash System

- Secondary

- Fuels

- Lubrication Oils

- Transmissions

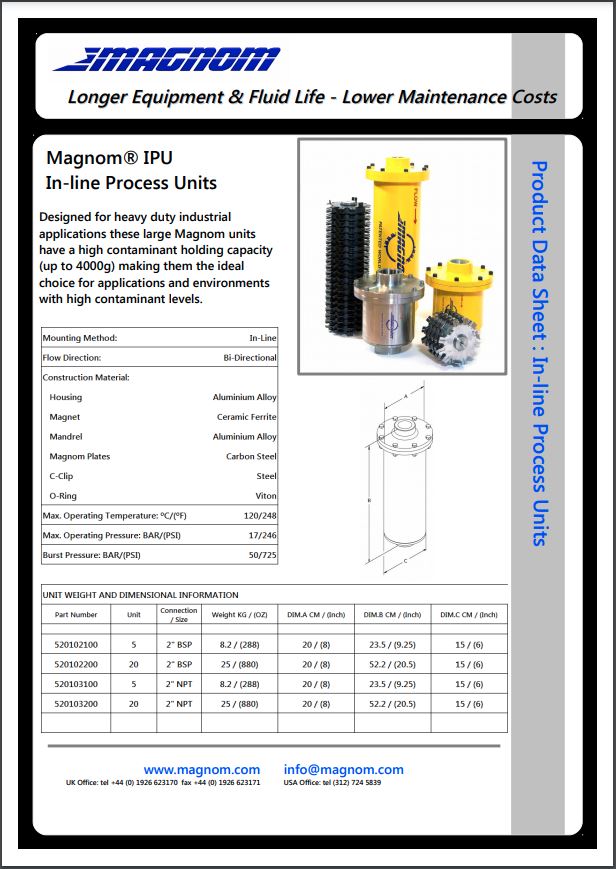

IPU- In,Line-Process-Units

The IPU 5 Core and 20 Core Inline Process Products have been designed for a very wide variety of fluid applications,

Especially suited to heavily contaminated ‘Rough Service’ applications, or where extended service intervals are a requirement.

With contamination capacities of up to IRO 1Kg & 4kg respectively between service/cleaning.

Designed for heavy duty industrial applications, these IPU Magnom™ units, have a very high contaminant holding capacity (size for size when compared to conventional filters) making them the ideal choice for applications and environments with high contaminant levels. The products have achieved great success within high viscosity fluids and in large scale transmission and central lubrication systems (Hydraulic and lubrication),

Special Features and Benefits:-

- In-Line fitment

- Non-Restrictive

- Suitable for high-viscosity fluids

- High contaminant holding capacity

- 100% efficient single pass

- Cleanable/reusable

Applications

- Lubricating – Oils

- Large hydraulic systems

- Transmissions [Large Scale]

- Fuels

- Coolants & Cutting Oils

- LPG & LNG Gas (Black Powder) etc…

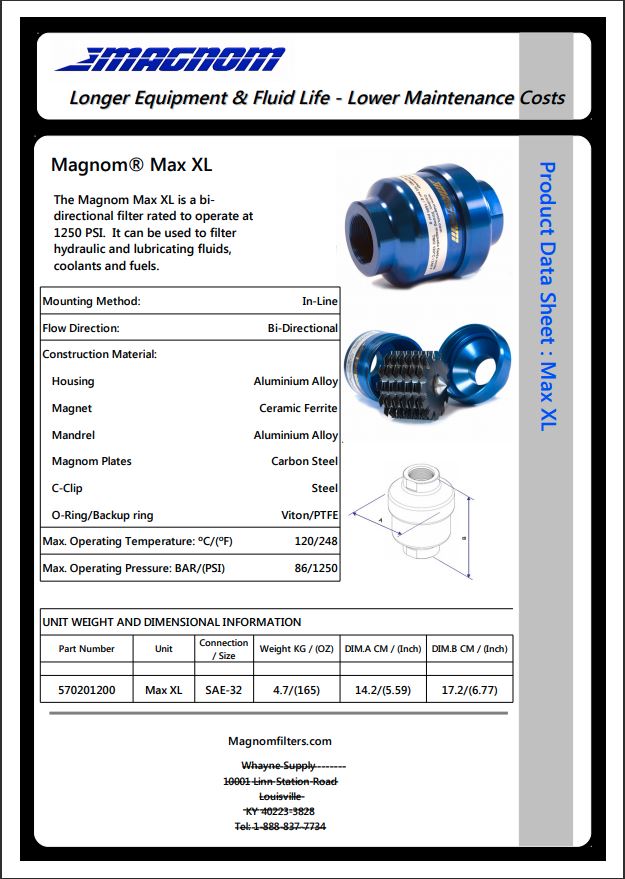

Max XL 2” & SAE-32 Machine & Transmission Filtration

Similar to our Mini Midi & Max range, the max XL series is a much higher capacity product, in terms of fluid flow, and contamination capacity, and is again one of the ‘work horses’ of the Magnom Product Range,

An in-line design, constructed in rugged anodised T6 aluminium alloy, these units deliver excellent performance and contaminant holding capacity.

They are frequently fitted to large “Off Highway” CAT type equipment and Wind Turbine gearboxes and transmissions.

Special Features and Benefits:-

- Compact,

- Very High Capacity, for extended service intervals.

- Standard SAE-32 & 2” NPT connections

- Bi-Directional

- 100% Efficient single pass to 4 micron

- Virtually eliminating pressure drop (even when full).

- Cleanable/reusable

Applications

- General Lubrication & Hydraulic Systems

- These Units are the Magnom™ of choice for fitment to lubricant and hydraulic systems and too many larger industrial and off highway Gearboxes & Transmissions, wind turbines, epicyclic systems

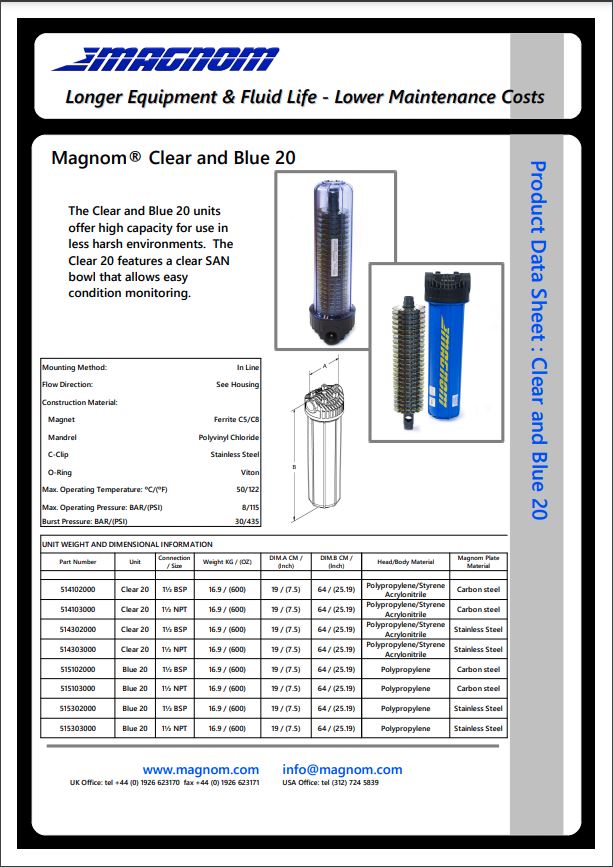

Blue 20” & Clear 20” Process Filtration

The Magnom™ Clear 20 & Blue 20’s, are industrial lighter duty solutions, the large 22 core Magnom™ unit has a very high dirt holding capacity (IRO up to 4Kg) making it the ideal choice for high contaminant environments and applications where rough service design is not essential.

The products have proved highly successful in metalworking environments for coolant and cutting oil clean up, often acting as a “Polishing Filter” cleaning up what all the other filtration has left in the circulation in systems.

The units features either a clear SAN bowl that allows easy condition monitoring of the contaminant build up.. or a Blue opaque Polyethylene bowl.

Special Features and Benefits:-

- The unit has a high contaminant holding capacity which makes it the ideal choice for high-contaminant environments.

- The units are the best low-cost alternative to the Magnom™ Process Unit and are suitable in e.g. metal working environments.

- The screw-on bowl makes the Magnom™ core easily accessible for inspection and cleaning, without disconnection of pipework

- Cleanable/reusable

Applications

- Coolants

- Cutting Oils

- Water systems

- Aqueous Wash Systems